Last Updated: 2021.02.05

to Japanese page

Fast Retailing engages in comprehensive quality and safety management to deliver secure, safe products to our customers. We work with partner factories to strengthen production management and improve technology, striving for higher levels of product quality.

Quality and Safety Management System

Comprehensive Quality and Safety Management

Comprehensive Quality and Safety Management

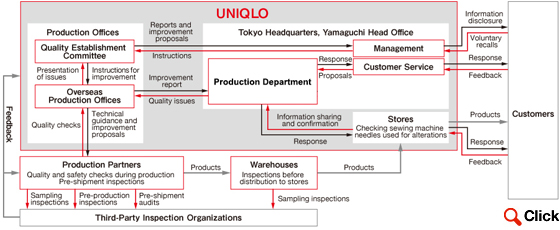

UNIQLO has adopted independent Global Quality and Safety Standards under which the company ensures quality and safety in its products. The UNIQLO Quality Assurance Committee, led by the officer in charge of production, determines these standards, which are even stricter than those required by the countries or regions in which the company operates. Production departments work with partner factories to ensure standards are enforced for all products.

Incorporating Customer Feedback to Improve Products

Incorporating Customer Feedback to Improve Products

UNIQLO receives customer feedback about product quality through stores and Customer Service Centers, which is collated by our Production Department. The Quality Assurance Committee and management respond promptly to any material product defects, determining whether to issue a recall for the product in question. The Production Department collates customer feedback by category, forming responses to improve quality according to the type and number of defects. The team then requests improvements be made at production offices around the world.

Quality and Safety Inspections

Quality and Safety Inspections

UNIQLO commissions advance testing of all materials by third-party organizations and other entities at the sample-making stage and again prior to mass production in order to confirm quality and safety. Advance tests include tests for color fastness*1 and formalin*2.

- *1 Color fastness tests: Tests designed to measure the durability of dyed products.

- *2 Formalin: Extremely small amounts of formalin (or formaldehyde) are sometimes used by clothing manufacturers as a shrink-proofing agent, anti-wrinkle agent, and softener during processing. However, this chemical has been known to cause eczema, rashes, or skin allergies in certain individuals.

UNIQLO also conducts pre-shipping inspections before finished products are dispatched from the factory, including checking for needles or other dangerous items. Third-party entities also carry out some pre-shipping inspections. We also commission the same third-party quality and safety inspections at G.U. Co., Ltd.

UNIQLO Quality and Safety Management System

Technical Support of Partner Factories Through Takumi (Textile Artisans)

UNIQLO owes much of the quality of its products to the Takumi Team, individuals who are leaders in Japan's outstanding textile industry expertise. Takumi consists of both textile takumi and sewing takumi. The Takumi Teams are stationed in UNIQLO production offices in China, Vietnam, and other locations, lending their expertise in textiles and sewing to partner factories in these countries. For example, Takumi Team members share dyeing and sewing techniques to help partner factories maintain high quality standards. The Takumi Team also provides guidance on occupational safety, working with partner factories to ensure safe working environments. This in turn leads to greater capacity and improved organizational infrastructure among our partners. As needed, Takumi Team members provide support to partners in their transactions with GU and other Fast Retailing Group businesses.

Takumi Team Teaching Sewing Machine Techniques

Voluntary Product Recalls

We make every effort to manage the quality of our products. However, in the event a defect is discovered by a customer, we report the information promptly to the Quality Assurance Committee and management, which determines whether a recall is necessary. Next, the Quality Assurance Committee implements measures quickly to prevent the recurrence of said quality defect. We publish information about product recalls and how to return products via the websites of each brand.